When sourcing paper packaging for food products, one of the most common questions from buyers is:

“What does GSM mean, and how does it affect the box?”

Understanding GSM (grams per square meter) and paperboard thickness is crucial for choosing the right material — ensuring your packaging is strong, safe, and visually appealing. This guide explains everything you need to know about GSM, thickness, and how it applies to food packaging.

1. What is GSM?

GSM (Grams per Square Meter) measures the weight of paper per unit area.

- Example: A paper with 300 GSM means that one square meter of the paper weighs 300 grams.

GSM is a standard measurement used globally to determine paper density and strength. Higher GSM generally means thicker, sturdier paper, but it’s not the only factor to consider.

2. Paperboard Thickness vs GSM

While GSM measures weight, thickness measures the physical height of the sheet in millimeters (mm) or points.

| Term | What It Measures | Importance for Food Packaging |

|---|---|---|

| GSM | Paper density (weight per m²) | Heavier GSM = stronger, more durable packaging |

| Thickness | Physical sheet height (mm) | Ensures structural integrity, stacking, and crush resistance |

Tip: Two boards can have the same GSM but different thickness depending on the paper type or manufacturing process.

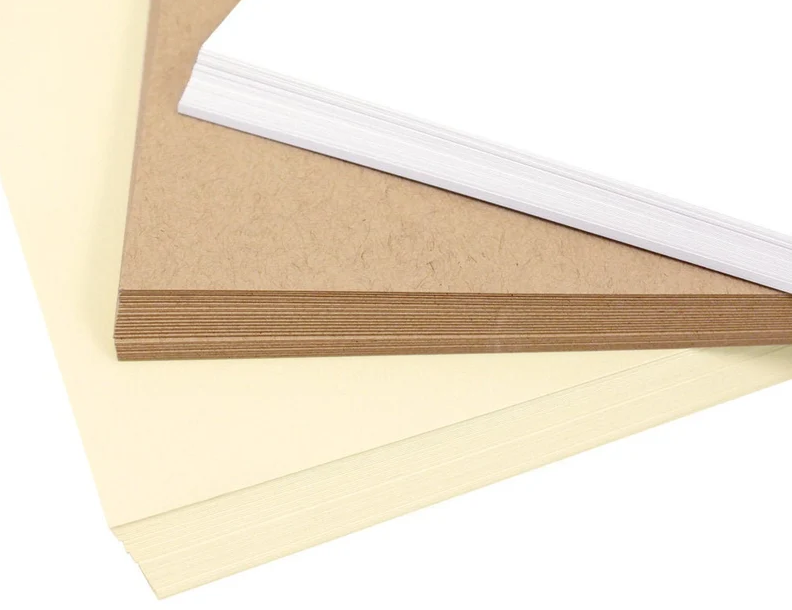

3. Common Paperboard Types and Typical GSM for Food Packaging

Different food products require different materials based on weight, moisture, and handling.

| Paperboard Type | Typical GSM | Typical Food Packaging Uses |

|---|---|---|

| Kraft Paperboard | 250–400 GSM | Burger boxes, takeaway boxes, bakery boxes |

| White SBS/FBB Board | 250–350 GSM | Snack boxes, frozen food sleeves, retail packaging |

| Coated Paperboard (PE / Water-Based) | 300–450 GSM | Frozen meals, ready-to-eat meals, greasy foods |

| Rigid Gift Board | 400–600 GSM | High-end chocolate boxes, gift sets |

4. How GSM Affects Your Packaging Performance

Strength & Durability

- Higher GSM provides better stiffness, stacking strength, and resistance to bending.

- Crucial for heavy meals, multi-layer boxes, or export packaging.

Printing & Finishing

- Lightweight GSM (250–300) works well for simple printing.

- Higher GSM (350–450+) is better for high-quality printing, embossing, foil stamping, and laminations.

Cost

- Higher GSM = more raw material = higher cost per box.

- Choosing the right GSM for your product ensures balance between cost and durability.

5. Selecting the Right GSM for Your Food Product

Here’s a practical guide based on product type:

| Product Type | Recommended GSM | Notes |

|---|---|---|

| Fast Food (burgers, fries) | 300–350 | Sturdy enough for takeaway and stacking |

| Ready-to-Eat Meals | 300–400 | Supports trays, coatings, freezer-safe applications |

| Cookies & Snacks | 250–300 | Lightweight yet protective |

| Bakery (cakes, cupcakes) | 300–400 | Can hold inserts and windows, prevents deformation |

| Gift Boxes / Chocolates | 400–600 | Premium feel, strong protection |

6. Additional Considerations for Food Packaging

- Moisture resistance: Choose coated paper for frozen meals or greasy foods.

- Eco-friendly materials: FSC-certified or recycled paper often requires slightly thicker GSM to maintain strength.

- Transportation: Long-distance shipping may require higher GSM for crush resistance.

- Stacking on shelves: Retailers may stack boxes; thickness and GSM prevent deformation.

7. Conclusion

Understanding GSM and paperboard thickness is essential for making informed packaging decisions. The right paper material not only protects your food but also enhances the perceived quality and branding of your product.

If you are planning your next packaging order and want expert guidance on choosing the perfect GSM and paperboard thickness, we can provide tailored recommendations for your product line.