As food brands and retailers increasingly focus on sustainability and regulatory compliance, the choice of coating for paper boxes has become a hot topic. European (EU) and U.S. buyers often ask whether to use water-based coating or traditional PE coating for their food packaging — especially with EUDR (European Union Deforestation Regulation) enforcement driving higher demand for eco-friendly materials in 2025.

Choosing the right coating is essential for protecting your product, enhancing shelf appeal, and positioning your brand as environmentally responsible.

1. What Are PE and Water-Based Coatings?

PE (Polyethylene) Coating

- A thin plastic layer applied to paper to make it moisture-resistant and grease-resistant.

- Commonly used for frozen foods, ready-to-eat meals, and takeaway boxes.

- Pros: Excellent water and grease resistance, strong durability.

- Cons: Harder to recycle unless separated from paper; not always EUDR-compliant.

Water-Based Coating

- Eco-friendly coating using water instead of plastic or solvents.

- Provides moisture and grease resistance without adding non-recyclable layers.

- Pros: Fully recyclable, EUDR-friendly, plastic-free; supports FSC and eco-labels.

- Cons: Slightly less water-resistant than PE (can be improved with modern formulations).

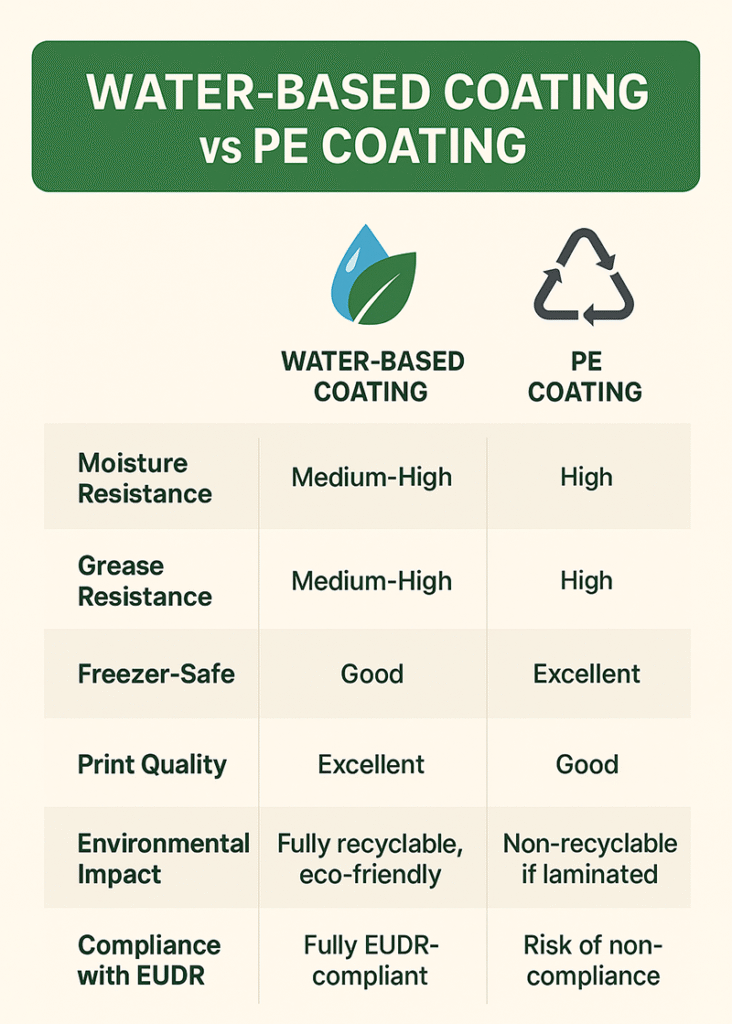

2. Performance Comparison: Water-Based vs PE

| Feature | PE Coating | Water-Based Coating |

|---|---|---|

| Moisture Resistance | High | Medium-High |

| Grease Resistance | High | Medium-High |

| Freezer-Safe | Excellent | Good (depends on GSM/thickness) |

| Print Quality | Good | Excellent (better ink adhesion) |

| Environmental Impact | Non-recyclable if laminated | Fully recyclable, eco-friendly |

| Compliance with EUDR | Risk of non-compliance | Fully EUDR-compliant |

| Brand Perception | Standard | Premium, sustainable |

3. Which Coating Should You Choose?

Choose PE Coating If:

- You package frozen foods or meals with sauces.

- Maximum moisture and grease protection is critical.

- Recycling infrastructure in your market is limited.

Choose Water-Based Coating If:

- Sustainability and ESG compliance are part of your brand strategy.

- You export to EU markets under EUDR regulations.

- You want premium, recyclable, and plastic-free packaging.

Many modern manufacturers now offer enhanced water-based coatings that can handle freezing and reheating, bridging the gap between performance and eco-friendliness.

4. The Marketing Advantage

Switching to water-based coatings not only meets regulatory requirements but also improves your brand image:

- Eco-conscious branding: Promotes plastic-free packaging to consumers.

- Retailer trust: EU & US retailers prioritize FSC/EUDR-compliant packaging.

- High shelf appeal: Modern, matte, and eco finishes attract premium buyers.

Brands that adopt water-based coatings early can differentiate themselves in a crowded frozen/ready meal market.

Detailed Comparison: Water-Based Coating vs. PE Coating

| Aspect | Water-Based Coating | PE Coating (Polyethylene) |

|---|---|---|

| Composition | Primarily water with a blend of natural materials (starch, cellulose, minerals) and minor synthetic polymers (like acrylics). | A thin layer of polyethylene, a thermoplastic made from fossil fuel-derived hydrocarbons. |

| Barrier Properties | Good resistance to water, grease, and mild acids, with the coating absorbing into the paper fibers. | Superior resistance (nearly 100%) to liquids, water, and grease, forming a distinct film layer on the surface. |

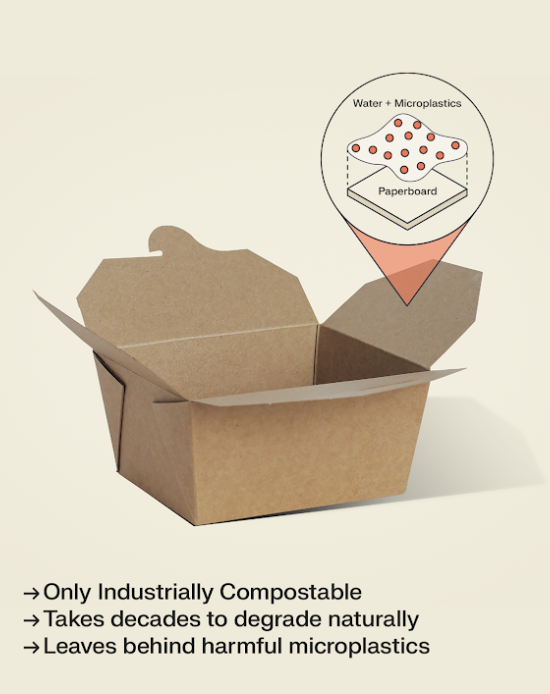

| Environmental Impact | Highly sustainable: biodegradable, compostable, and fully recyclable in standard paper streams. It has a lower carbon footprint. | Low sustainability: non-biodegradable, takes hundreds of years to degrade, and requires specialized, complex recycling processes. |

| Recycling/Waste | Easily recycled; the coating dissolves during the re-pulping process, allowing for high fiber recovery. | Difficult to recycle effectively in standard facilities, often contaminating the paper recycling stream and ending up in landfills. |

| Cost | Generally has a higher upfront cost. | Cost-effective and widely available, with a simple application process. |

| Applications | Widely used in food packaging (e.g., paper cups, fast-food containers) as an eco-friendly option. | Dominant in food packaging, industrial applications, and various consumer goods where durability and strong moisture barriers are essential. |

5. Cost Considerations

While water-based coatings may slightly increase unit cost compared to PE-coated boxes, the benefits include:

- Higher resale value due to sustainable branding.

- Reduced regulatory risk in EU and global markets.

- Long-term compliance with deforestation-free sourcing rules.

Overall, many exporters find eco-friendly packaging pays off in both brand reputation and market access.

6. Conclusion

Both PE and water-based coatings have their place in food packaging. The choice depends on your product type, market requirements, and sustainability goals.

- Frozen meals or greasy foods: PE may still be preferred.

- Retail-ready, sustainable packaging for EU/US markets: Water-based coating is the smarter, future-proof choice.

If your brand wants EUDR-compliant, recyclable, and premium-quality paper boxes, we can help you select the right coating for your product.