For many brands sourcing packaging, one of the first questions is simple:

“How much do custom paper boxes cost?”

The answer depends on a combination of factors — from box size and paper type to printing options and order quantity. Understanding these elements not only helps you plan your budget but also ensures you get the best value when placing large-scale orders.

Below is a clear, practical guide to help buyers estimate packaging costs before requesting a quote.

→ Request a Quote

1. Box Size: The Primary Driver of Cost

The size of the box determines how much raw material is needed. Larger boxes require more paper, higher-strength board, and often larger printing plates.

General rules:

- Bigger box = higher material cost

- Unique shapes or extra height may require stronger paper or reinforcement

- Flat shipping boxes cost less than rigid structures

If you already know your product size, providing L × W × H (in cm or mm) helps suppliers calculate accurate pricing quickly.

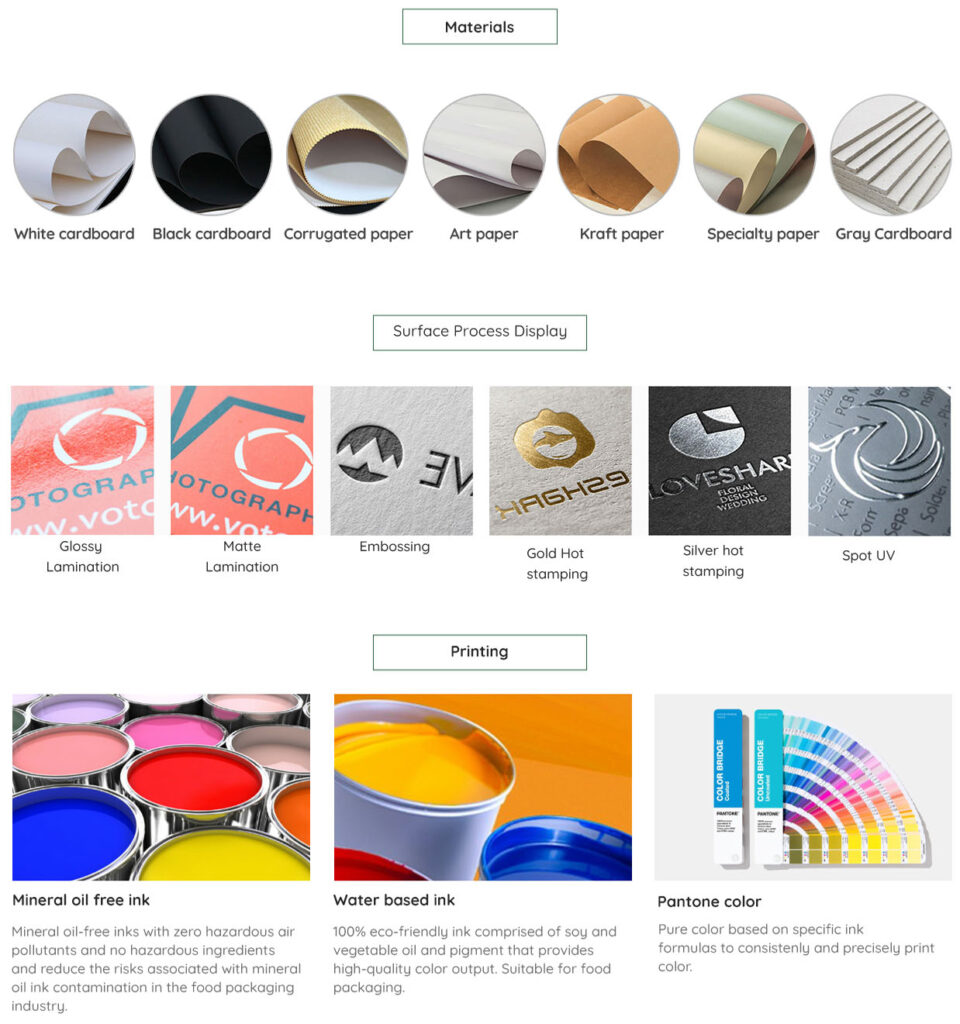

2. Paper Type and Thickness

Different paper grades have different price levels, and the board thickness affects durability and cost.

Common paper options:

- Kraft paperboard (cheapest, eco-friendly)

- White C1S / C2S board (premium printing quality)

- Food-grade kraft for takeout and ready meals

- FBB/SBS board for beauty, snacks, retail goods

How thickness affects price:

- 250–300gsm → economical, light products

- 300–400gsm → retail boxes, bakery boxes

- 400gsm+ → heavy-duty, frozen food, premium packaging

Choosing the right material ensures stability without overspending.

3. Printing & Finishes (One of the Biggest Cost Variables)

Printing complexity can dramatically influence price. Good packaging attracts attention, but each extra step adds cost.

Cost-impacting print options:

- CMYK full-color printing (standard)

- Pantone color printing (extra charge)

- Spot UV / matte / gloss coating

- Foil stamping (gold, silver, holographic)

- Embossing or debossing

- Die-cut windows with clear film

Tip: For bulk orders, high-quality CMYK printing normally provides the best cost-to-impact ratio.

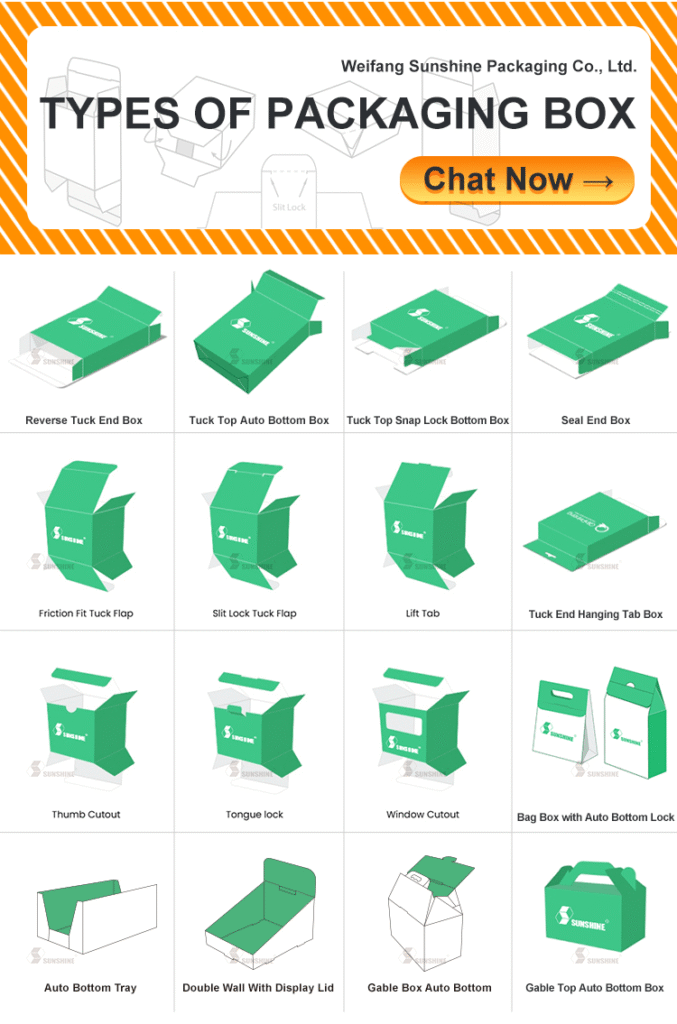

4. Box Structure and Assembly Style

Some structures are simple, while others require more material or longer production time.

Lower-cost structures

- Tuck-top box

- Mailer box

- Standard folding carton

Higher-cost structures

- Rigid gift boxes

- Drawer-style boxes

- Multi-layer boxes with inserts

- Custom die-cut shapes

Adding paper inserts, dividers, or handles also increases material and labor cost.

5. Order Quantity (MOQ)

This is where most buyers save money.

The higher the quantity, the lower the unit price — because setup costs are spread across more boxes.

Typical MOQ ranges

- 1,000 pcs → suitable for small brands; unit cost highest

- 3,000–5,000 pcs → factory MOQ for most custom boxes

- 10,000+ pcs → best unit price for wholesalers & large brands

If you want the most accurate quote, decide your quantity first.

6. Special Requirements: Food Contact, Frozen Grade, or Eco Materials

Certain categories require certified or coated materials, which affect pricing.

Adds to cost:

- Food-grade paper

- Freezer-safe paper for frozen meals

- Grease-resistant coatings

- Water-based or biodegradable coatings

- FSC-certified paper

For B2B brands, these features are often necessary to meet retailer or importer requirements.

7. Shipping Cost and Packaging Method

Your location and shipping preference impact the overall budget.

Key considerations:

- Shipped flat-packed (cheaper)

- Shipped fully assembled (higher shipping volume)

- Carton size and weight

- Sea freight vs. express shipping

If you’re planning a long-term supply chain, ask about bulk pallet shipping for the lowest logistics cost.

8. How to Get a Fast, Accurate Price Quote

To receive an exact quotation from a packaging supplier, prepare:

- Box size (L × W × H)

- Paper material & thickness

- Printing requirements

- Quantity (MOQ or multiple tiers)

- Sample requirement (if needed)

- Destination country

The clearer your details, the faster the supplier can calculate an accurate quote — often within 12–24 hours.

Conclusion

Estimating the cost of custom paper boxes is easier when you understand the factors involved. By considering size, material, printing, and quantity, you can plan production more efficiently and avoid unexpected expenses.

If you’re preparing for a new product launch or want to compare pricing for large-scale orders, our team can help with detailed cost breakdowns and material recommendations.