Behind every well-designed box on a retail shelf, there is a precise manufacturing process that brings the idea to life. As a professional paper box manufacturer and OEM packaging supplier, we combine technical craftsmanship with modern production equipment to ensure each order meets international quality standards. This guide walks you through our step-by-step workflow — from concept development to final packing — so you know exactly how your packaging is made.

Learn more about our production capabilities → About Our Factory

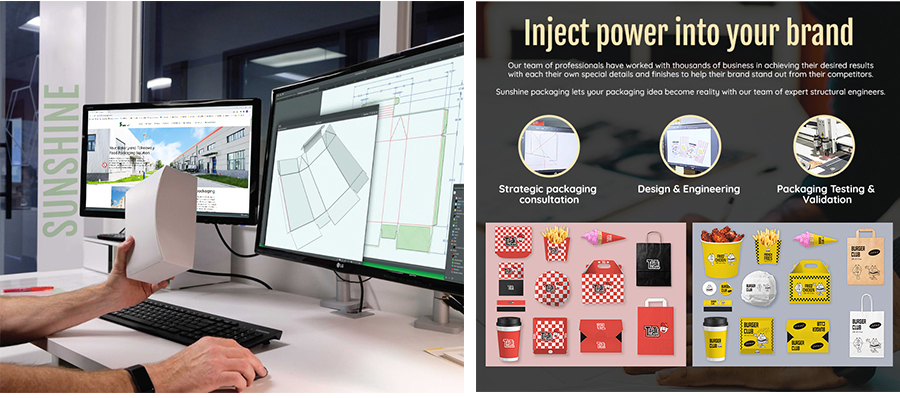

1. Understanding Your Packaging Needs

Every project begins with communication. We take time to understand your product, branding goals, timeline, and budget. This includes:

- Box style and dimensions

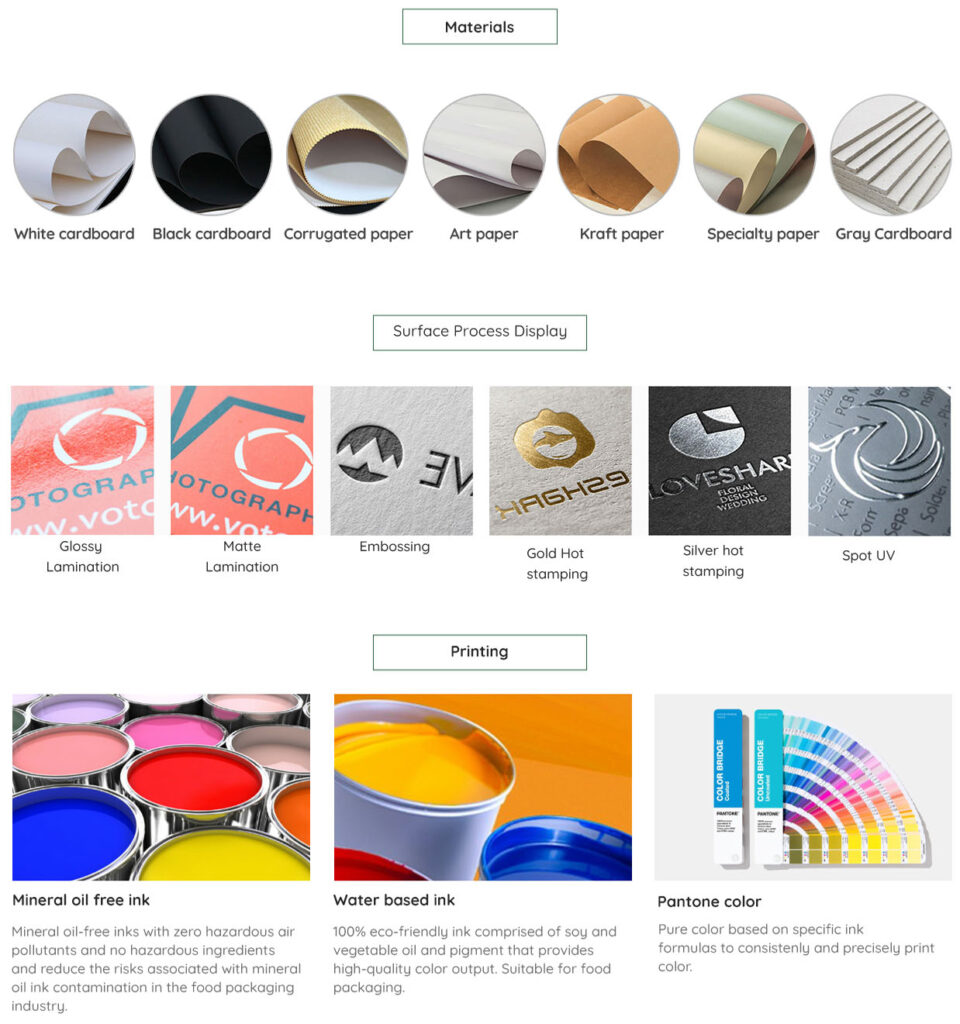

- Paper type and thickness

- Printing requirements

- Surface finishes (matte, gloss, foil, embossing)

- Food-grade or eco-material needs

- Quantity and shipping terms

Clear information at this stage helps us recommend the most cost-effective and structurally reliable solution for your brand.

2. Structural Design & Dieline Development

Once specifications are confirmed, our engineering team creates a custom dieline, which defines the cutting and folding pattern of the box.

What happens here:

- Structural testing to ensure stability

- Crease line optimization for smooth folding

- Material usage review to reduce waste

- Prototype creation (digital proof or physical sample)

This stage ensures your packaging fits perfectly, protects the product, and runs efficiently on packing lines.

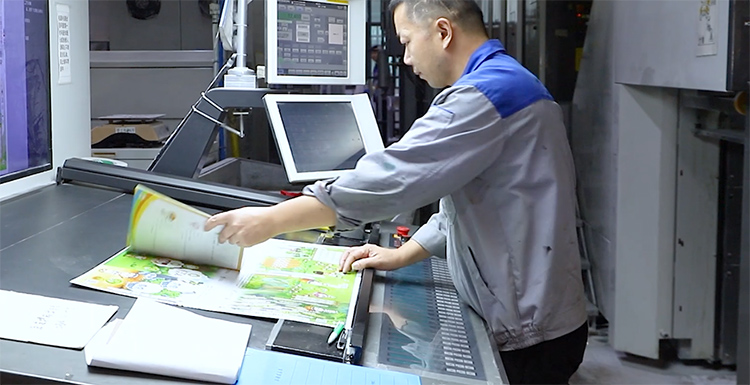

3. High-Quality Printing

After the dieline is approved, the artwork goes through pre-press checks, including color calibration and resolution control.

Printing methods we use:

- Offset CMYK printing for retail-quality graphics

- Pantone printing for exact brand color consistency

- Food-safe inks for food-contact packaging

Color accuracy is one of the most important elements for brand owners. Our press operators monitor every sheet to ensure even color coverage and sharp detail.

4. Surface Finishing for Brand Impact

To enhance appearance and durability, we apply finishing effects tailored to your product category.

Available finishes:

- Matte or gloss lamination

- Aqueous or UV coating

- Foil stamping (gold, silver, holographic)

- Spot UV highlights

- Embossing or debossing

- Anti-scratch and moisture-resistant coatings

These details elevate shelf impact and protect the box during transportation and storage.

5. Precision Die-Cutting

Once the printed sheets are ready, they move to our automatic die-cutting machines.

This stage ensures:

- Clean and accurate edges

- Perfect alignment with the printed artwork

- Smooth crease lines for easy folding

- Reduced waste and better material efficiency

Our tooling is maintained regularly to guarantee consistent performance, even for large-volume orders.

6. Gluing and Forming the Boxes

Die-cut sheets are transferred to automatic gluing machines or manual assembly stations depending on the complexity of the box.

Examples:

- Tuck-in boxes → automatic gluing

- Auto-lock or crash-bottom boxes → semi-automatic

- Rigid gift boxes → hand-assembled for precision

We perform multiple adhesive tests to ensure strong bonding, clean edges, and correct forming angles.

7. Quality Control at Every Stage

Quality control is integrated throughout the entire production line—not just at the final stage.

Our QC procedures include:

- Material inspection (paper GSM, thickness, surface texture)

- Color accuracy checks during printing

- Die-cutting precision measurement

- Gluing strength tests

- Drop tests and load-bearing checks for shipping cartons

- Final inspection based on AQL standards

International buyers depend on packaging consistency. Our QC team ensures your boxes meet the exact specifications you approved, batch after batch.

8. Packing, Palletizing & Shipping Preparation

Once approved, boxes are flat-packed unless otherwise requested. Proper packaging prevents damage during long-distance sea or air shipping.

We provide:

- Export-grade cartons

- Film wrapping for moisture protection

- Custom palletizing

- Shipping labels and documentation

- FSC / food-contact certificates when needed

You receive packaging that arrives clean, intact, and ready for your packing line.

9. Continuous Support After Delivery

For OEM partnerships, production doesn’t stop at shipping. We maintain long-term communication to support reorders, adjust specifications, develop new packaging, and provide suggestions based on your market trends.

Our goal is to help your brand grow with packaging that is dependable, consistent, and aligned with your retail strategy.

Conclusion

Creating a high-quality paper box requires more than printing and cutting — it’s a coordinated process involving engineering, precision equipment, and strict quality control. From initial concept to the finished product on a store shelf, every step is designed to protect your brand and enhance its presence.

Want to learn more about our manufacturing capabilities or discuss a custom project?

👉 About Our Factory