Introduction

Crispy, juicy fried chicken has been an all-time crowd favorite. As fried chicken restaurants and chains multiply rapidly across the globe, packaging plays a vital role in securing those delicate golden-brown pieces maintained fresh and crunchy until consumers take a bite.

That’s where chicken boxes come in handy!

However, with a dizzying array of boxes out there catering to poultry and fried food, how do pick the right one for your restaurant?

This blog post will cover all you need to know about chicken boxes including:

Table of Contents

Let’s get into all the info you need for savvy chicken packaging!

Why Should Restaurants Invest in Good Chicken Packaging?

For restaurants specializing in chicken, packaging plays an outsized role in securing food freshness and preventing sogginess during transit apart from table presentation.

Here are the reasons to use customized chicken boxes rather than basic food containers:

Preserve Crispiness – Chicken boxes engineered with steam vents or moisture absorbent pads avoid condensation build-up leading to loss of the coveted crispiness.

Display Golden-Brown Visual – See-through cutouts and sleeve windows enable showcasing the tempting golden-fried visual rather drab containers. This further boosts perceived value.

Reinforce Branding – Tailored packaging designed with brand logos, colors and graphics act as subtle advertising to customers. This can boost recall and drive reorders.

Enhance Customer Experience – Attractive packaging signals care for the customer’s experience rather than just cost-cutting on basic containers.

Prevent Leaks & Splattering – Grease-proof and tear-resistant liners protect crispness while preventing oily leaks making transit messy.

For maximal product quality until consumption, specialized chicken boxes tick all the right boxes! Pun intended.

Materials For Chicken Boxes

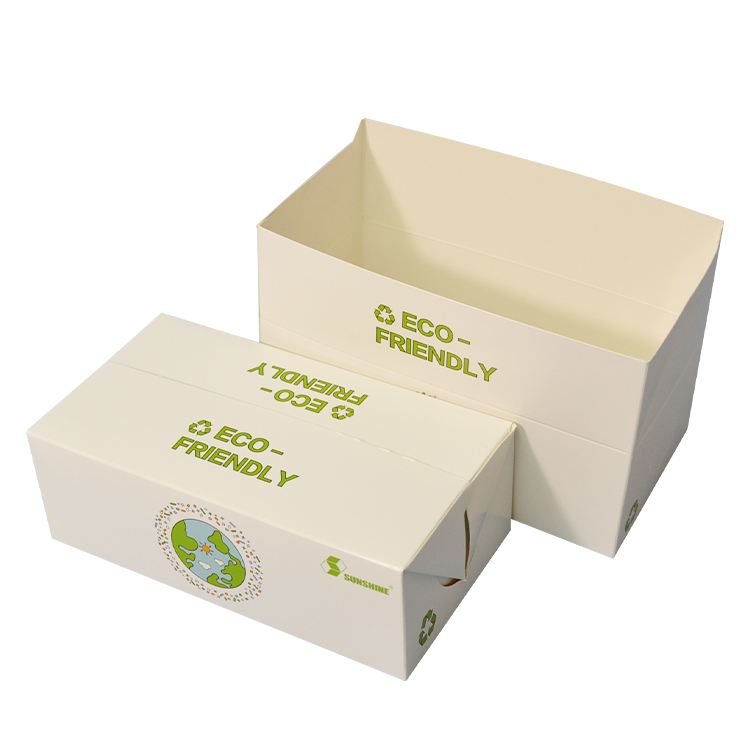

When selecting materials for chicken boxes, it’s crucial to prioritize both food safety and environmental sustainability. Opting for materials such as food-grade cardboard or paperboard ensures that your packaging maintains the integrity and freshness of the chicken while being safe for direct food contact. Additionally, considering eco-friendly options like recycled or biodegradable materials, such as sugarcane fibers or bamboo pulp, can minimize your environmental footprint and appeal to environmentally conscious customers. By choosing the right materials, you can ensure that your chicken boxes meet both quality and sustainability standards.

Indicative Pricing Breakdown

Here is the indicative price range for custom printed chicken boxes based on popular order quantities:

| Box Type | Size | Order Quantity | Price Range |

|---|---|---|---|

| Chicken Box | 10” x 8” x 3” | 250 boxes | $300-$400 |

| Chicken Box Tray | 12” x 12” x 3” | 500 boxes | $450-$600 |

| Chicken Clamshell | 8”x8”x3” | 1000 boxes | $600-$800 |

| Chicken Bucket | Combo | 5000 boxes | $1000-$1500 |

Naturally, elevated customization complexity like foil stamping, embossing, window cutouts entail higher pricing. Nevertheless, the indicative pricing table above covers typical chicken packaging formats like boxes, buckets, trays and clamshells across common order quantities.

FAQs

Here are some common queries around chicken packaging answered:

Q. What materials work best for chicken boxes?

Cardboard and kraft paper work optimally for chicken boxes as they decent insulation to retain heat or cold for freshly fried chicken or chilled chicken respectively while being cost-efficient. Special liners enhance grease resistance.

Q. Are there fully compostable or recyclable chicken boxes too?

Yes, innovative materials like bagasse pulped from sugarcane waste make excellent renewable and compostable substrates for eco-friendly chicken boxes without compromising on food protection abilities.

Q. Can chicken boxes be customized into unique shapes?

Through die-cut techniques, chicken boxes can be molded into interesting shapes like stars, hearts, drums associated with the brand logo or identity. Circular rotating trays also maximize visibility from all sides.

Q. How long can chicken stay fresh inside quality boxes?

Properly engineered chicken boxes with moisture absorption pads and ventiliation maximize hold periods for up to 60 to 90 mins for peak crispness experience, provided there is no piling up creating steam condensation.

Conclusion

As chicken continues to be a staple across quick-service restaurants and snack counters, specialized packaging preserves that coveted crunch and visual appeal enticing customers. Investing into sturdy chicken boxes tailored to handle such oily and moisture-sensitive food pays back through superior protection from kitchen to table and even during commuting back home.

With functionality as top priority, clever chicken packaging also incorporates enticing see-through exposure of the real product unlike bland containers. This further drives cravings and perceived value regarding the quality inside. So serve your signature chicken recipes in tailored boxes as unique as your secret spice mixes!