Custom Paper Box Solutions for Food Brands & Manufacturers

We specialize in custom paper boxes for food packaging,

with a focus on snack products.

Designed for brands that require functional structures, stable supply, and scalable production — not generic packaging.

Food packaging boxes

What We Help Food Businesses Solve

We don’t just print boxes — we engineer packaging that works in real food operations.

Reduce packaging cost through structure and material optimization

Deliver paper boxes that perform in heating, takeaway, logistics, and shelf display

Ensure stable, long-term supply for mid-to-large volume orders

Align packaging design with real production and filling conditions

We are certified by FSC, ISO, Sedex, BRC, BSCI, SGS, and FDA food grade, ensuring both quality and compliance.

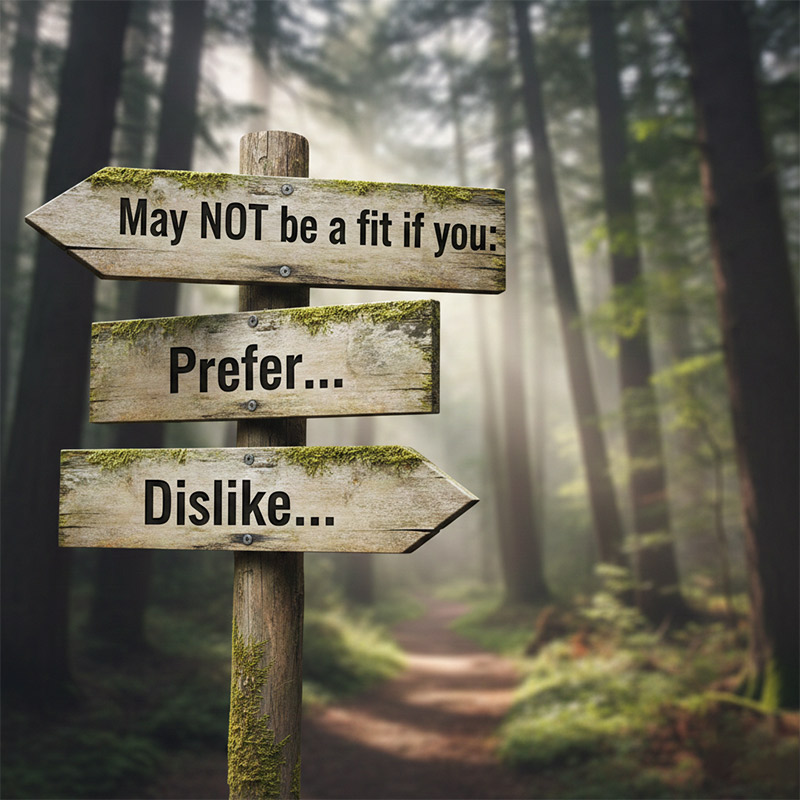

Is This the Right Fit for You?

This clarity helps both sides save time.

– A food brand or food manufacturer

– Looking for custom paper box packaging

– Managing stable or scalable order volumes

– Seeking a long-term packaging partner, not a one-off supplier

– Only need small or irregular quantities

– Focus mainly on paper cups, paper bowls, or paper bags

– Are looking for the lowest price rather than structural performance

▼

Our Core Paper Box Solutions

Snack Food Packaging

Shelf-ready paper boxes optimized for branding visibility, structural stability, and automated packing lines, supporting volume growth.

Fast Food & Takeaway Packaging

Durable paper boxes optimized for grease resistance, secure transport, and high-volume foodservice operations.

Bakery & Confectionery Packaging

Presentation-focused paper boxes engineered for product protection, structural stability, and premium retail display performance.

Ready-to-Eat & Dry Food Packaging

Retail-optimized paper boxes designed for durability, shelf efficiency, and scalable high-volume food production.

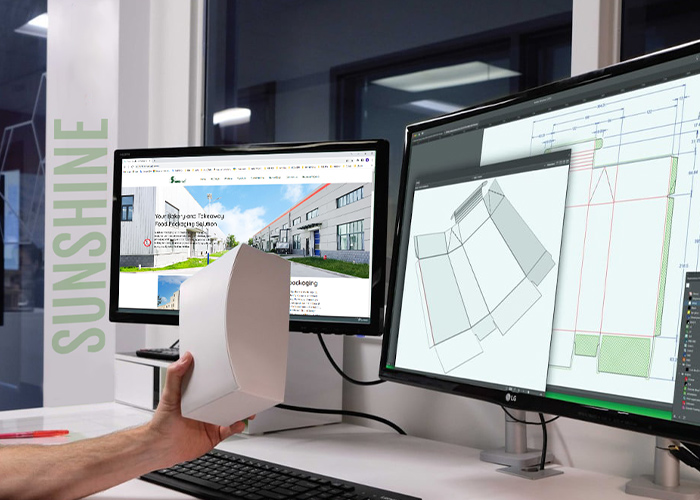

Folded & Die-Cut Box Structures

We focus on box structure engineering, not just printing — ensuring efficiency in production, packing, transport, and retail display.

About Me

Packaging Built Around Food Business Models

Because effective packaging starts with understanding how your food is produced, distributed, and sold.

We work closely with food businesses that operate in:

▶Snack Food Packaging production

▶Fast Food & Takeaway production

▶Bakery & Confectionery production

▶Ready-to-Eat & Dry Food production

Our packaging solutions balance:

▶ Food safety compliance

▶ Cost vs. durability

▶ Supply consistency

▶ Operational efficiency

How We Work

- Requirement understanding & application analysis

- Structure and cost optimization

- Sampling and testing

- Mass production with quality control

Order Size & MOQ

Our minimum order quantities are designed for brands and manufacturers with stable or growing demand, ensuring production efficiency and consistent quality.

Start a Serious Packaging Discussion

If your business fits the criteria above, we’d be glad to explore how our paper box solutions can support your food packaging needs.

👉 Please contact us through the inquiry form to help us understand your requirements clearly.

We focus on long-term cooperation with food brands and manufacturers requiring custom paper box solutions.

Small quantity or non-box packaging inquiries may not receive immediate responses.